Understanding Conveyor Belt Lacing

In the realm of industrial machinery, the term conveyor belt lacing emerges as a cornerstone of operational efficiency. It represents the essential techniques and materials used to join segments of conveyor belts, ensuring a seamless transfer of goods across assembly lines. The precise integration of lacing solutions not only enhances durability but also contributes to the safety of the machinery by preventing slippage and wear. This imperative aspect of industrial operations is frequently overlooked but has a significant impact on productivity. In various industries, including manufacturing, food processing, and logistics, effective lacing serves as the unsung hero that upholds the integrity of conveyor systems and drives overall success.

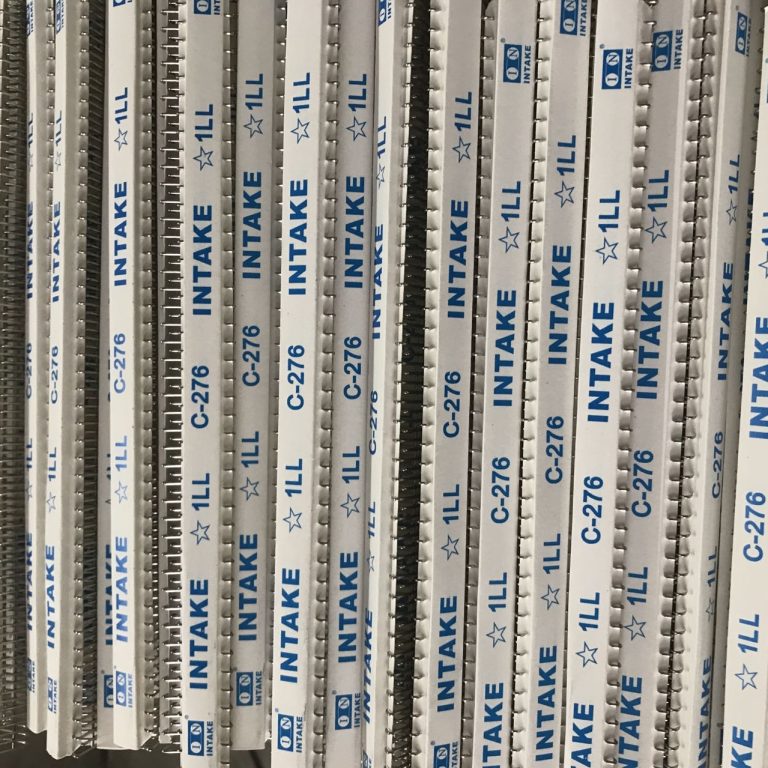

The Significance of Welded Metal Bar Lacing

Within the spectrum of conveyor belt lacing solutions, welded metal bar lacing stands out as an innovative approach to enhancing conveyor functionality. This method involves the fusion of metal bars to create a robust lacing system that can withstand rigorous operational demands. Industries that require heavy-duty conveyor systems find this particularly beneficial, as it provides a reliable means of belt reinforcement. The durability of welded metal bar lacing ensures that even in high-traffic environments, the risk of belt failure significantly diminishes. Such reliability translates into lower maintenance costs and increased uptime, empowering businesses to focus on core operations rather than frequent repairs.

Practical Applications of Conveyor Belt Lacing

When considering the widespread applications of conveyor belt lacing, it is crucial to acknowledge its role in ensuring the smooth functioning of various sectors. In food processing, for instance, specialized lacing techniques are vital to maintaining hygiene standards while maximizing throughput. Conveyor lacing also plays a pivotal role in packaging and sorting, where the precision of movement can have a direct impact on efficiency. By facilitating a continuous flow of products, businesses can streamline operations and enhance customer satisfaction. Furthermore, the adaptability of lacing materials allows for customization according to specific operational needs, highlighting its versatility across multiple applications.

Conclusion: The Advantage of Choosing Intake

In summary, the critical role of both conveyor belt lacing and welded metal bar lacing in promoting operational efficiency cannot be overstated. Their applications in various industries underscore their importance in ensuring continuous and smooth operational flow. As businesses seek to optimize their processes, the choice of high-quality lacing solutions becomes paramount. It is advisable to consider renowned manufacturers such as Intake, known for their exceptional supply advantages and commitment to providing reliable products. By partnering with Intake, enterprises can not only enhance their machinery performance but also secure a competitive edge in today’s dynamic market landscape.